RAIL CAR INDUSTRY

colorbox_move

RAIL CAR INDUSTRY

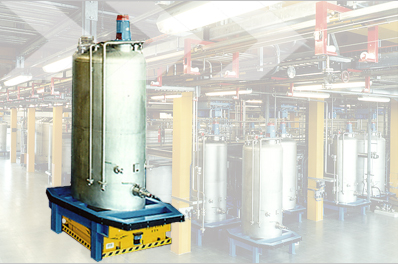

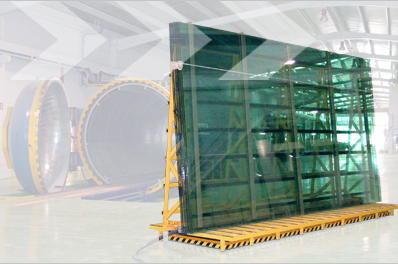

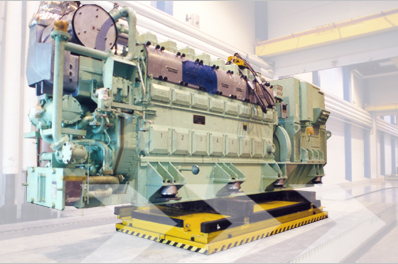

Air cushions enable the flexible factory

Air cushion technology allows new factory layouts to be realised and modern manufacturing concepts implemented in the rail car industry. This allows slow, rigid and expensive transport systems such as gantry cranes, fixed rail systems, traversers and assembly pits to be largely dispensed with.

Air cushion technology transforms dark, solidly built factory buildings dating from the last century into modern, clean and transparent industrial complexes.

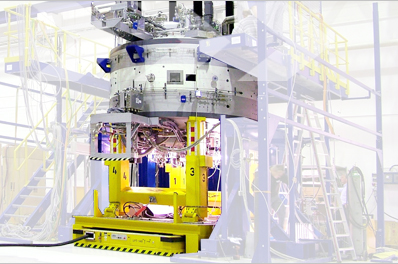

Semi-automated transport of the superstructures is provided by tape-guided robot vehicles comprising 2, 3 or more transporters that communicate wirelessly with each other. Only one operator is required to control this system.

Air cushion-guided elevating platforms, work platforms and handling equipment are also used for assembly work.

OTHER BENefits:

- High flexibility and simple adaptation to new products and production processes

- Investment costs are reduced, productivity boosted and cycle times shortened

- Vehicles of different lengths can be transported to the assembly stations: there are no fixed assembly stations, as these can be located anywhere and can be reached by the air cushions at any time

- Use of standardised support stands for all vehicles capable of being transported on air cushions

- Uniform, flexible air cushion-capable assembly platforms with several levels that surround the vehicles

- Safe, non-hazardous way of transporting the vehicles

- Transport system easy to be operate by one employee floating load enables exact positioning accuracy

- Floating load enables exact positioning accuracy

- Assembly and measuring equipment led on air cushions (underfloor assembly, doors, corner load weighing unit)

- Air cushion-borne bogie/motor bogie transport equipment for high-bay warehouses