ELECTRICAL INDUSTRY

colorbox_move

ELECTRICAL INDUSTRY

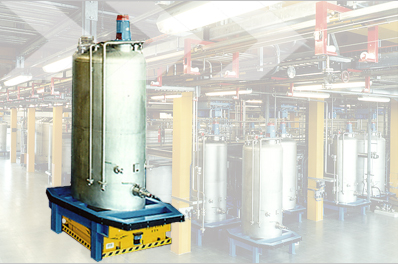

DELU has set new standards in the Indoor transport of heavy transformers.

DELU has set new standards in the Indoor transport of heavy transformers.

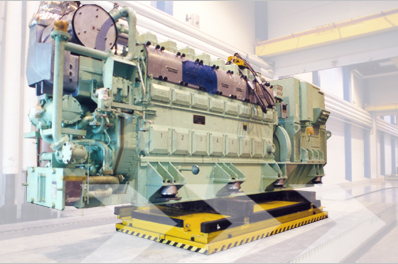

Large power transformers can weigh as much as 700 tons or more. To move these leviathans within a factory, huge, bulky crane or rail systems are required. These challenges make the advantages of an air cushion system particularly apparent.

DELU supplies low-cost pallet transport systems that allow transformers weighing up to 1,000 tons to be positioned to millimetre precision and safely manoeuvred through narrow passageways by a single operator.

Such a system can comprise several (small) transports that are combined and arranged in different ways (parallel, inline) according to the size and distribution of the load. This enables the whole product spectrum of 10 to 1,000 tons to be covered easily and economically.

Complete transformers or components are placed on steel pallets, which means they can be picked up by the air cushion transporter at any time and conveyed to the next assembly station, the testing lab or the VPD. The hall crane is only required for the loading and unloading of the pallets. It is usually possible to dispense with inflexible rail systems entirely.

Other benefits:

- High flexibility and simple adaptation to new products and production processes

- Load range can be easily expanded by DUO mode or expansion modules

- Investment costs are reduced, productivity boosted and lead times shortened

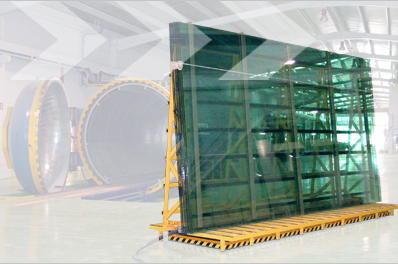

- Compact design and optimal space utilisation saves valuable space

- Transport pallets can be used universally (transformers, active parts, tanks, coils)

- Transformers transported quickly and safely

- Transport system is easy for one operator to operate, even in DUO mode

- Floating load allows precise positioning

- Wide load distribution helps protect the floor

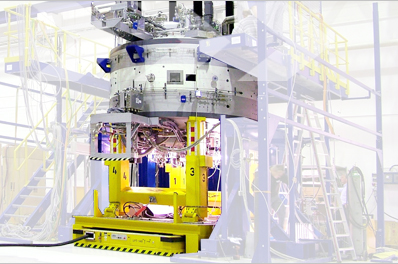

- VPD bridges suitable for air cushions

- Forked-shaped transporters for loading the press